I was one of three CEC air specialists who traveled to the joint Society for Mining, Metallurgy & Exploration (SME) and the Colorado Mining Association (CMA) Smart Mining: Resources for a Connected World conference at the end of February. The technical program was organized into 137 different sessions containing over 600 presentations. As an air quality practitioner and fellow presenter, I thought it would be helpful to review all 50 air-related abstracts and summarize the key topics of interest to today’s mining sector.

Rock and Coal Dust

By far, the most popular topics were rock and coal dust in subsurface mines. Over a third of the air-related presentations addressed aspects of these topics. Several papers focused on measures to mitigate subsurface miner exposures to dust through either dust collectors or enhanced ventilation. One paper introduced a new technique for de-dusting of worker garments that has been shown to be effective at reducing occupational exposures.

Second in number to the topic of mitigating miner exposures were presentations that addressed means to enhance the delivery of rock dust, whether wet, dry, or in a foam, to help prevent coal dust explosions. Several presentations addressed techniques for characterizing the physical makeup of mine dust samples as well as monitoring and sampling method improvements.

Finally, for surface mining operations, a “digital mine” that utilizes real-time monitoring of multiple parameters and an Internet of Things approach to enable comprehensive dust control management was discussed.

Ventilation

Closely related to dust exposures and control were presentations discussing subsurface mine ventilation. About 20% of the air presentations focused on this topic. Several presenters discussed efforts to understand and model air flow patterns to better protect workers from inhalation exposures. Computational fluid dynamics modeling was discussed by several presenters as a tool to reduce health risks to miners through a better understanding of gas migration and dust transport. In one case, the ventilation requirements of diesel equipment in subsurface mines were presented in support of guidelines on how to reduce the cost of ventilation systems needed for such equipment.

Instrumentation and Sensors

The topic of monitoring instruments and sensors was just as popular as ventilation. One author presented an early-warning system that processes data from a subsurface atmospheric monitoring system through machine learning and artificial intelligence algorithms to enhance accident intervention actions. Other innovations were presented in the areas of:

- Multi-gas meters;

- Personal dust monitoring techniques;

- Real-time miner exposure monitoring; and

- Sensor monitoring for ventilation control.

Another presentation acknowledged the promise of big data as a way to better understand subsurface mine atmospheric conditions, but argued that given the costs of gathering and processing massive quantities of data, one must make a careful comparison of the value gained to the costs. The goal of that author’s research was to optimize the number of sensors needed to manage ventilation conditions and prevent health hazards.

Diesel Particulate Matter

Second to rock and coal dust, the most talked-about atmospheric contaminant was diesel particulate matter (DPM). DPM presentations focused primarily on measurement and analytical methods. Presenters discussed real-time monitoring techniques and improvements to laboratory analyses. In that latter case, a portable technique using Fourier transform mid-infrared spectrometry for rapid on-site sample characterization was discussed. In addition to measurement methods, exposure mitigation strategies were discussed. One presenter discussed a fogging scrubber that can be used to improve a miner’s air space. More effectively improving air quality for miners, another author called for the elimination of diesel equipment from use in subsurface mines altogether.

Carbon Dioxide and Climate Change

While not strictly a mining issue, five presentations focused on issues related to either carbon dioxide control directly or climate change in general. Research was presented on efforts underway to capture carbon dioxide from fossil fuel power plant flue exhaust using alkali scrubbing solutions. Another presentation discussed conversion of captured carbon dioxide from coal-fired power plant exhaust to a commercial product, oxalic acid. Other presentations addressed risks to mining operations associated with climate change as well as the application of artificial intelligence and deep learning models to reducing greenhouse gas emissions from surface mining operations.

Air Permitting

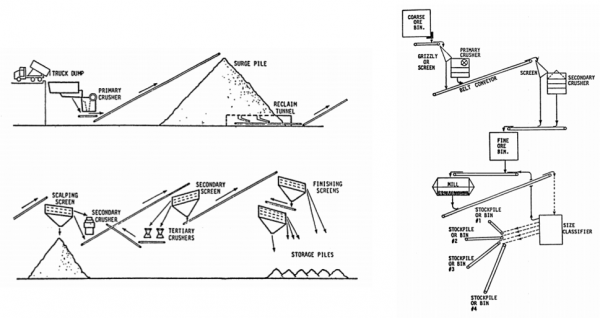

Four speakers, including two from CEC, presented on topics related to air permitting. CEC’s air experts spoke about permitting strategies for mining Appalachian coal and the permitting and compliance issues associated with aggregate mining and processing plants. The other related topics were developments in atmospheric dispersion modeling requirements applicable to the mining industry and Best Available Control Technologies for mine methane emissions.

Conclusion

The exposure to and mitigation of subsurface miner inhalation health risks was the dominant theme of air-related presentations at this year’s SME/CMA conference. Advances in real-time and portable instrumentation coupled with enhanced mitigation measures aim to reduce worker exposures. Use of big data and advanced modeling techniques for the monitoring and management of subsurface ventilation systems promises to help further reduce such exposures. If you have any questions about the information presented here, please contact Kris Macoskey at 800-365-2324 or via email at kmacoskey@cecinc.com.

Post a Comment