Dealing with zebra mussels is a sticky business, especially for power, drinking water, and industrial plants that rely on U.S. waterways to conduct daily operations.

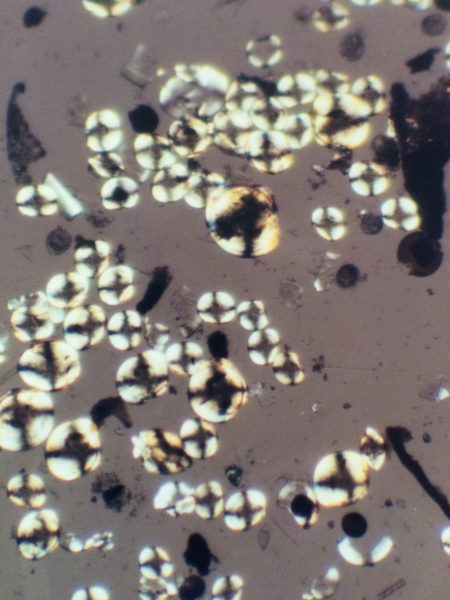

Aquatic biologists theorize that zebra mussels, a species of freshwater bivalve mollusk, were introduced to the Great Lakes in the 1980s by a ship carrying ballast water from Eastern Europe. These mussels have three characteristics that makes this nonindigenous species problematic to North American water users. The first is its microscopic free-living veliger form, which is so small it can easily glide through the screens used by most industries to filter out unwanted natural water source byproducts. The second is that each female adult mussel can produce up to one million of these veligers each year. Most importantly is that it is the first freshwater mussel species in North America that has the ability stick to hard surfaces.

“Since their introduction, zebra mussels have and continue to invade a great number of rivers and tributaries beyond the Great Lakes, causing issues for many industries,” says Cameron Lange, CEC Principal and nationally recognized nonindigenous, aquatic nuisance species expert.

When in veliger form, the zebra mussels can drift long distances until they find the right environment to settle and grow into large mats of adult mussels, according to Lange. Often the best environments are the hard surfaces — such as pipes and screens — inside power, drinking water, and manufacturing plants. They can quickly cause impacts such as constricting intake water flow, which can hamper daily operations. And if not treated, this nuisance species can cause long-term damage, as well. The mussel mats build up on one another, creating mats upward of three-quarters of a meter thick at times.

Lange shared some horror stories that happened early in their introduction to the U.S. Those ranged from water facilities shutting down during Christmas, which rendered the facility unable to provide drinking water to local communities, to a power plant shutting down, causing expensive maintenance and potentially affecting service.

“The build-up of mussel mats can cause some really serious impacts because eventually the mussels on the inside of the mat die and rot because they no longer have access to food or oxygen. So they ablate, coming off all at once because the dead ones can no longer attach,” explains Lange. “These big clumps of mussels, called druses, then drift further into the power plant or facility.”

Lange describes that the way most of the facilities work is there is a big pipe drawing water in, and it constricts into smaller and smaller pipes. When a large mat of mussels makes its way through the pipe system, sooner or later it can fit through, causing an immediate outage or problems because the blockage is preventing flow for areas that are needed.

Staying Ahead of the Game

So how can water-dependent industries prevent zebra mussels from disrupting business? Lange says it starts with choosing a firm with expertise in dealing with the species. With more than 30 years’ experience, Civil & Environmental Consultants offers a number of services to help treat existing zebra mussels, as well as prevent future damage caused by the invasive species.

“For example, in areas where the zebra mussels aren’t present but they’re likely to be, CEC offers monitoring services,” says Lange, “where we go out and take water samples and then examine the samples to see if the veligers are present in the water column. We also set artificial substrates where we can take a look and see whether anything is attached to the substrates in the area.”

Concurrent with monitoring, a “system’s vulnerability analysis” is performed by studying the body of water to determine the likelihood of mussels actually proliferating in the water should they get introduced and examining the facility’s system to see where zebra mussels may cause issues.

“By monitoring and analyzing an area before the zebra mussels are introduced, it provides facilities with time to develop and implement controls,” says Lange. “This data is paramount to determine what type of treatments might be available to treat and prevent issues within a facility.”

Every Client is Unique

Lange says it is important to note that treatment and controls are not one size fits all. Each project is specific to the facility and its environment, which is why experience with the species is of great importance.

“Our clients expect an environmentally sound, functional control system that is economically feasible,” says Lange. “To do that, you really have to have knowledge of what treatment options are available and how they will perform in certain situations to protect the facility and its systems.”

To demonstrate the importance of understanding the unique nuances of each client, Lange shared an experience working with a botanical garden, which used water from their ornamental ponds for irrigation and air conditioning through an intricate system of pipes.

“For years, the botanical garden was protected because their water did not have zebra mussels,” explains Lange. “But then they needed perform maintenance on one of the ponds, so they drew it down and refilled it unknowingly with zebra mussel contaminated water.”

The solution for this client was complicated because they couldn’t allow mussels to infest the sprinkler system, and chemicals normally used to protect such a system could not be utilized because of their potential to harm the ornamental plants. To mitigate the mussels, the team designed an ultra-fine mesh filter that could remove all particles down to about 125 microns in order to remove all the mussel veligers from entering the system.

“It was a challenging project because the restrictions required our team to think outside traditional treatments and controls,” shared Lange. “But that kind of emphasizes, although that was a real unique system, every system you look at is different and how you control them is as different as every system. Sometimes it comes down to not only what you have to do, like prevent chemicals from spilling on plants like in this case, but also a lot of times the facility only want certain treatments and controls, so you have to adjust their needs. It’s a collaborative process.”

Post a Comment